Unlocking the Secrets of the Best Cocoa Drying Machine Key Specifications for Optimal Performance

As the global cocoa market is projected to reach a staggering USD 10.7 billion by 2025, the importance of efficient processing equipment, particularly the Cocoa Drying Machine, becomes increasingly crucial for manufacturers striving to maintain quality and reduce costs. According to a recent industry report, approximately 35% of cocoa producers cite inadequate drying methods as a significant factor affecting chocolate quality and production efficiency. Optimal performance of these machines not only enhances the flavor development during fermentation but also minimizes mold risks, ensuring that cocoa beans meet stringent quality standards. In this blog, we will delve into the key specifications of the best Cocoa Drying Machines available in the market, offering essential tips for manufacturers to unlock the secrets to maximizing their performance and contributing to a more sustainable cocoa industry.

Understanding the Importance of Cocoa Drying Machines in Production Efficiency

Cocoa drying machines play a vital role in the production of high-quality cocoa products. Proper drying is crucial because it affects the flavor, color, and overall quality of cocoa beans. If cocoa beans are not dried adequately, they may develop undesirable flavors and harbor moisture, leading to spoilage and reduced shelf life. Thus, investing in efficient cocoa drying technology is paramount for manufacturers aiming to enhance production efficiency and product quality.

Cocoa drying machines play a vital role in the production of high-quality cocoa products. Proper drying is crucial because it affects the flavor, color, and overall quality of cocoa beans. If cocoa beans are not dried adequately, they may develop undesirable flavors and harbor moisture, leading to spoilage and reduced shelf life. Thus, investing in efficient cocoa drying technology is paramount for manufacturers aiming to enhance production efficiency and product quality.

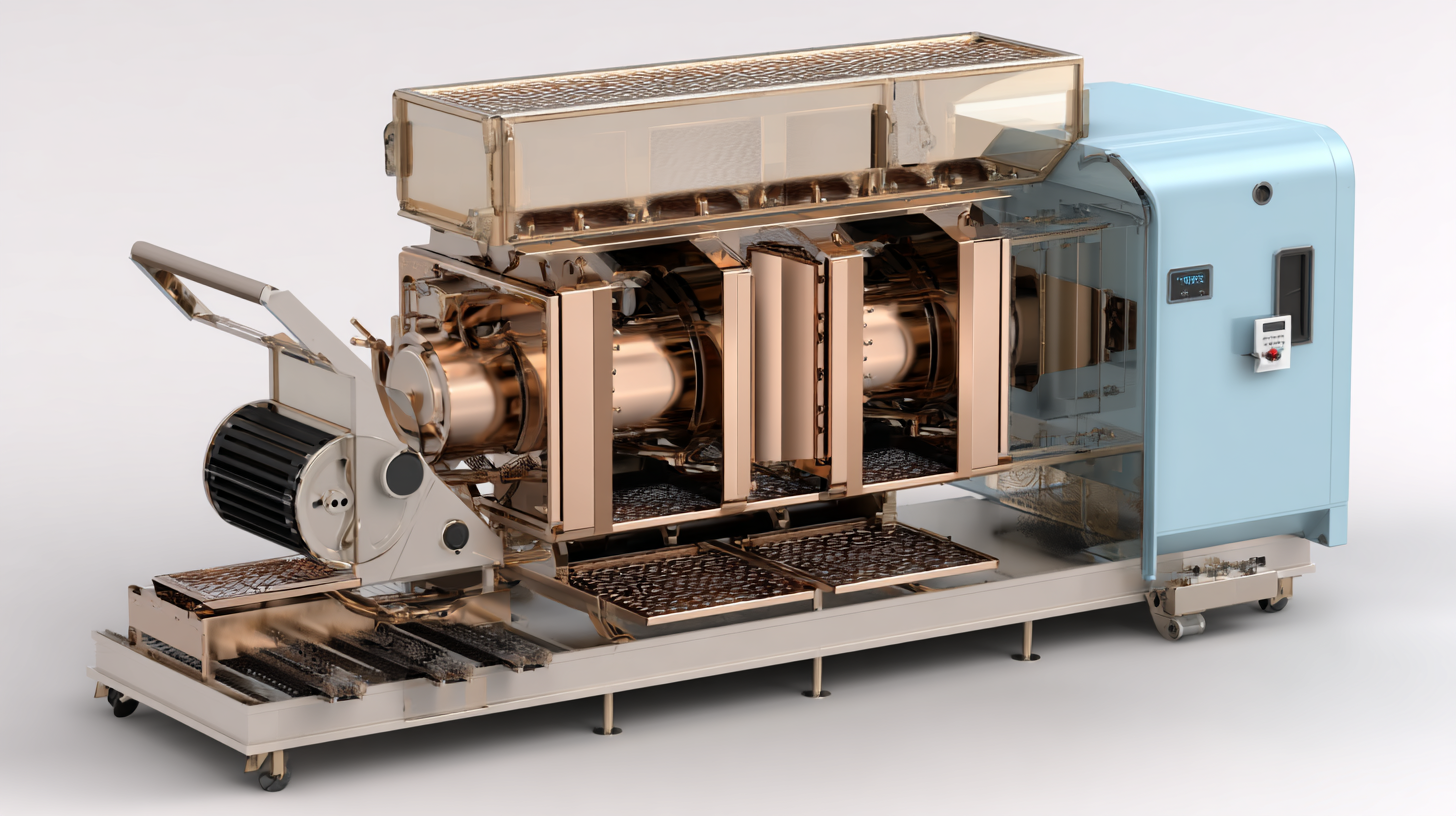

Understanding the key specifications of cocoa drying machines can significantly improve operational outcomes. Features such as adjustable temperature settings, humidity control, and airflow management are essential for achieving optimal drying conditions. Machines equipped with advanced monitoring systems can provide real-time data, enabling producers to fine-tune the drying process for the best results. By prioritizing these specifications, manufacturers can ensure their drying operations are consistent, efficient, and ultimately contribute to a superior end product in the competitive cocoa market.

Key Specifications to Look for in High-Quality Cocoa Drying Equipment

When selecting high-quality cocoa drying equipment, several key specifications are essential to ensure optimal performance and efficiency. First and foremost, the drying capacity of the machine should align with your production needs. A machine that can process a larger volume of cocoa in a shorter period will enhance productivity and ensure timely processing. Additionally, look for machines with adjustable drying temperature settings, as the ability to control heat is crucial in preserving the flavor and aroma of the cocoa beans while effectively removing moisture.

Another important specification to consider is the energy efficiency of the drying equipment. Machines designed with advanced thermal technology or energy recovery systems can substantially reduce operational costs and environmental impact. Furthermore, ensure the equipment features a reliable airflow system, which is vital for even moisture distribution and uniform drying. This balance helps to prevent over-drying or under-drying of the beans, ultimately leading to higher quality cocoa. By focusing on these specifications, you can select equipment that not only meets your current needs but also supports long-term, sustainable cocoa production.

Common Issues Faced by Cocoa Drying Machines and Their Solutions

Cocoa drying machines play a crucial role in ensuring the quality of cocoa beans, but they often come with their fair share of operational challenges. One common issue is uneven drying, which can lead to the growth of mold and affect the flavor profile of the beans. To combat this, it’s essential to regularly calibrate the machine’s airflow settings and maintain consistent temperature control. Implementing batch drying schedules can also enhance uniformity.

Another prevalent problem is the buildup of residual moisture. If not addressed, this can lead to spoilage and loss of product quality. To mitigate this, operators should regularly conduct moisture tests on the beans and adjust drying times accordingly. Additionally, integrating humidity sensors can provide real-time data to optimize the drying process more effectively.

Tips: Always clean the drying chamber after each use to prevent contamination and ensure optimal airflow. Regular maintenance checks on the heating elements and fans can prevent unexpected breakdowns. Implementing a log for monitoring drying conditions can help in identifying patterns and addressing recurrent issues proactively.

Best Practices for Maintaining Optimal Performance of Cocoa Dryers

When it comes to maximizing the efficiency and longevity of cocoa drying machines, adhering to best practices is crucial. One key aspect is to regularly inspect and maintain the equipment. Regular cleaning of the drying chambers and heat exchangers ensures that there are no obstructions that could hinder airflow or energy efficiency. It’s also essential to check for any buildup of cocoa residue, as this can affect the quality of the cocoa and the performance of the machine.

Another tip is to monitor the temperature and humidity levels during the drying process. Optimal drying conditions not only prevent spoilage but also enhance the flavor profile of the cocoa. Using a digital control system can help in maintaining precise parameters, enabling operators to make timely adjustments. Regular calibration of sensors and controls will also ensure that the machine operates within the ideal range.

Lastly, training personnel on the proper operation of the cocoa dryer cannot be overlooked. Well-informed staff can better detect anomalies and address issues promptly, leading to more consistent performance. Routine training sessions will keep the team updated on best practices and safety measures, ensuring the cocoa drying process remains efficient and effective.

Innovative Technologies Transforming Cocoa Drying Processes Today

Innovative technologies are reshaping the cocoa drying process, making it more efficient and sustainable. Traditional drying methods often lead to inconsistent results and can negatively impact the quality of cocoa beans. However, modern cocoa drying machines incorporate advanced features such as precise temperature control and automated humidity monitoring, ensuring that beans dry evenly. This technological evolution minimizes the risk of mold and other quality-damaging factors, ultimately contributing to superior cocoa products.

Moreover, the integration of smart sensors and IoT capabilities in cocoa drying machines allows for real-time data analysis and remote monitoring. This means that producers can track the drying conditions from anywhere, adjust parameters on-the-fly, and significantly reduce energy consumption. As the cocoa industry continues to embrace these cutting-edge technologies, producers can optimize their drying processes, boost productivity, and enhance the flavor profiles of their cocoa beans, setting the stage for a new era of cocoa quality.